| Availability: | |

|---|---|

| Quantity: | |

AF-80AT

FITLIFE

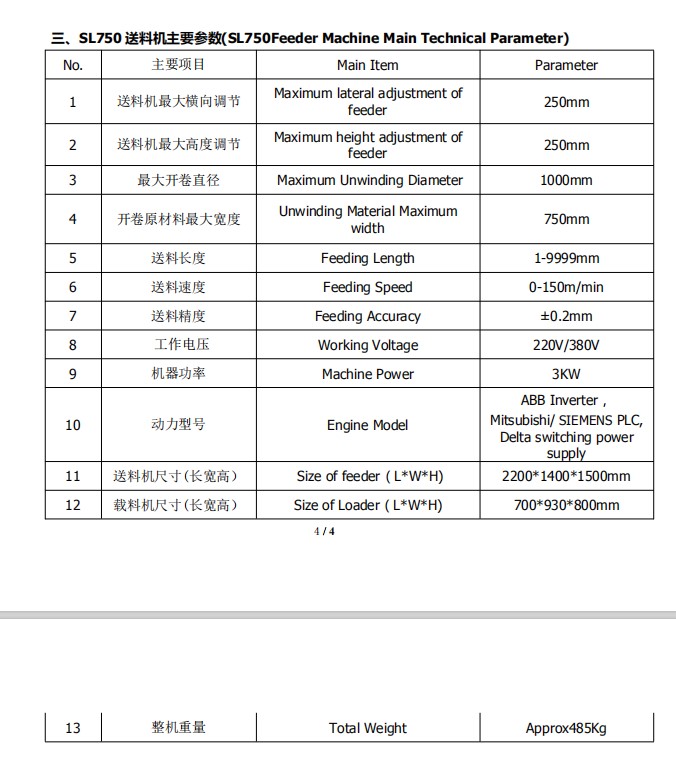

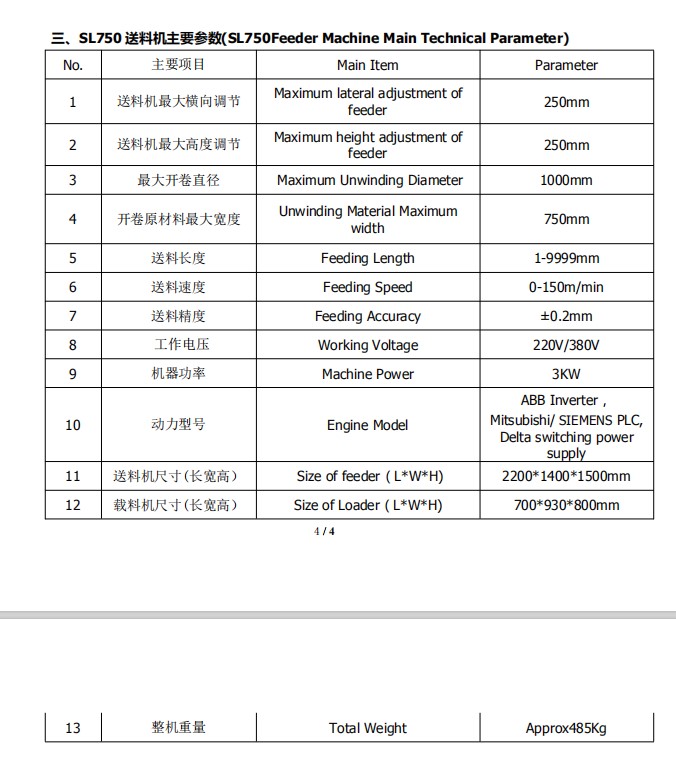

Fitlife Aluminum Foil Container Production Line (Upgraded Model) is

composed of auto-lubricated feeder machine SL750, length controller, control panel,

80T pneumatic punch machine, mould (price is not included), conveyor,

stackor collector of finished product, scrap collector (optional equipment)

and scrap presser (optional equipment).

Mould Characters:

There is a good saying that only a good mould can

manufacture good products---that is our long-term aim. Abandoning the

out-date methods of producing moulds, we use advanced technology to

produce mould. We adopt flexible rebounded device in the process of

making mould. The mould is long-lived, in good-quality, highly precise

and reasonable designed. The excellent processing technical ensures that

we can complete the cutting, shaping, stretching, curling once in a time.

A series of perfect product is available, such as both footwall mould

and multi-cavities mould, from mould of one grid to multi-grids mould,

and moulds of different rims (G type, L type, IVC type, and Fold type).

The mould is excellent in quality and reasonable in price. The working cycle

period is fast. In the light of different clients’ needs, we will make

out different solution, for example, special electroplating processing.

According to customer’s needs, the mould can be steed up to ordinary punch,

pneumatic punch, or the press with four pillars.

◆Scrap Collector

It is served for collecting the scraps during the production in

order to prevent the scrap remains inside the mold from effecting the

blow-away of finished products. With the scrap collector, the labor

intensity is reduced dramatically, the efficiency is improved and the

sanitary situation of factory is improved as well.

◆Scrap Presser

It is served for pressing and packing the scrap to convenience the

recycle of the scrap which can improve the recycled efficiency, reducing

the labor intensity, saving manpower and field occupation and lowering

the expense of transportation.

Fitlife Aluminum Foil Container Production Line (Upgraded Model) is

composed of auto-lubricated feeder machine SL750, length controller, control panel,

80T pneumatic punch machine, mould (price is not included), conveyor,

stackor collector of finished product, scrap collector (optional equipment)

and scrap presser (optional equipment).

Mould Characters:

There is a good saying that only a good mould can

manufacture good products---that is our long-term aim. Abandoning the

out-date methods of producing moulds, we use advanced technology to

produce mould. We adopt flexible rebounded device in the process of

making mould. The mould is long-lived, in good-quality, highly precise

and reasonable designed. The excellent processing technical ensures that

we can complete the cutting, shaping, stretching, curling once in a time.

A series of perfect product is available, such as both footwall mould

and multi-cavities mould, from mould of one grid to multi-grids mould,

and moulds of different rims (G type, L type, IVC type, and Fold type).

The mould is excellent in quality and reasonable in price. The working cycle

period is fast. In the light of different clients’ needs, we will make

out different solution, for example, special electroplating processing.

According to customer’s needs, the mould can be steed up to ordinary punch,

pneumatic punch, or the press with four pillars.

◆Scrap Collector

It is served for collecting the scraps during the production in

order to prevent the scrap remains inside the mold from effecting the

blow-away of finished products. With the scrap collector, the labor

intensity is reduced dramatically, the efficiency is improved and the

sanitary situation of factory is improved as well.

◆Scrap Presser

It is served for pressing and packing the scrap to convenience the

recycle of the scrap which can improve the recycled efficiency, reducing

the labor intensity, saving manpower and field occupation and lowering

the expense of transportation.